Luoyang HUANA Precision Bearing Technology Co., Ltd., located in Luoyang,precision bearing production base in China, is a comprehensive enterprise specializing in the design, development, production and sales of precision bearings and non-standard bearings. Our company has a group of experienced bearing designers, a dedicated sales team and an experienced production team.

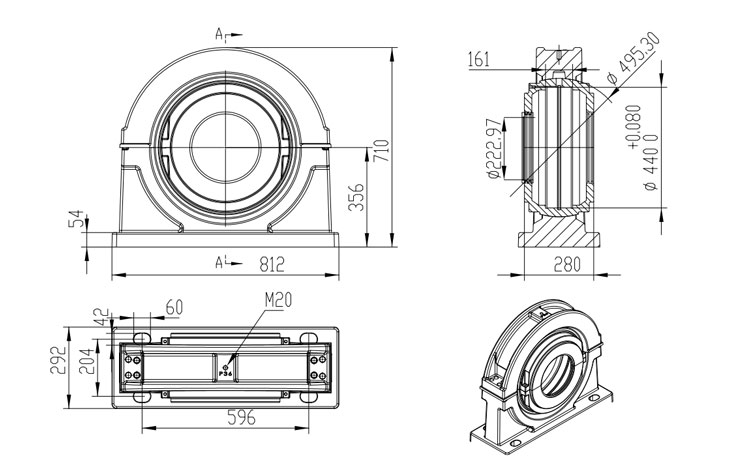

Our company mainly produces precision thin section bearings, precision angular contact ball bearings, precision cylindrical roller bearings, precision tapered roller bearings, precision thrust ball bearings, precision thrust roller bearings, precision slewing bearings, precision cross roller bearings, precision YRT bearings, excavator bearings, etc.

The products are widely used in precision machine tools, port machinery, mining, medical, coal, cement, oil drilling, wind power generation, industrial robots, national defense industry and other fields.

Our company has implemented strict process control from the whole production process of raw materials entering the factory - turning - heat treatment - grinding - hole processing - raceway superfinishing - finished product assembly. Effectively ensure 100% pass rate

We adhere to the tenet of "elaborately manufacturing and serving the world", and wholeheartedly provide users with high-quality products and all-round services.

Tel

Tel WeChat

WeChat

Msg

Msg TOP

TOP